|

|

Expert 5K+

Posts: 9679

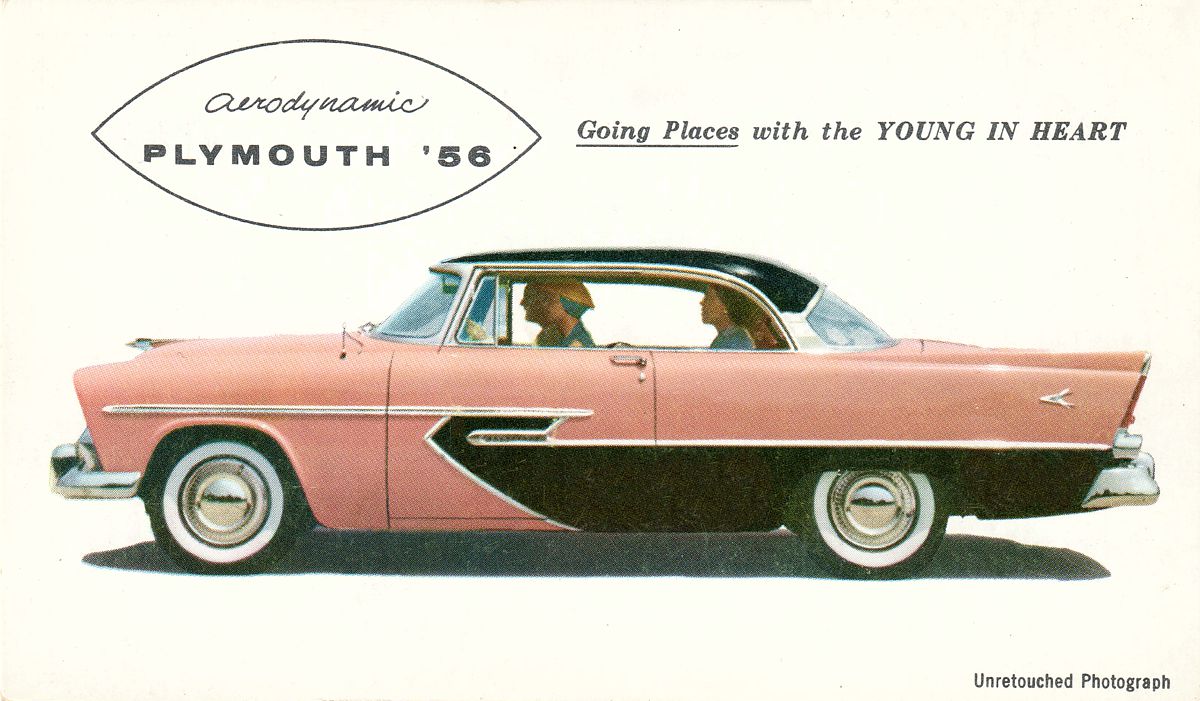

Location: So. Cal | I bought this car from the same seller I got the yellow '56 Fury from. I may purchase another '56 Plymouth parts car from him as well. This is a really neat car that I like more than the Fury. Nice color combo and interior fabrics on this. Manual steering, manual brakes, but has dual rear antennae (like my Fury does), dash clock, plastic seat covers (Bottoms are still good), Hollywood wheel, rear bumper wings, 277 motor that turns, powerflite, push button radio. No radiator so I will probably just install an aluminum one and paint it black. The back window is busted out of it that caused the demise of the upper back seat upholstery so I will need to replace that and fix the seat. It came with a replacement window, so that's good. I didn't want to have to hunt one down. But I'll probably install a new headliner into it first.

Hopefully I can get the motor running, fix the brakes and get it driving pretty quickly. The paint is actually in decent shape except in front of the rear wheels where it is rusted. I plan to fix the rust and repaint the white, but just buff & wax the rose color as it is. It should come out looking great. I'll leave the powerflite in it for the time being, unless it's bad, at which point I would swap it out for a torqueflite or push button 727. I will work on this car right after I get the brakes done on the Fury and get it cleaned up as much as I can.

(56Belvy Arrives.jpg) (56Belvy Arrives.jpg)

(56Belvy LR.jpg) (56Belvy LR.jpg)

(56Belvy Dash.jpg) (56Belvy Dash.jpg)

Attachments

----------------

56Belvy Arrives.jpg (270KB - 413 downloads) 56Belvy Arrives.jpg (270KB - 413 downloads)

56Belvy LR.jpg (211KB - 402 downloads) 56Belvy LR.jpg (211KB - 402 downloads)

56Belvy Dash.jpg (155KB - 407 downloads) 56Belvy Dash.jpg (155KB - 407 downloads)

|

|

| |

|

Expert 5K+

Posts: 7403

Location: northern germany | Oh, thats pretty! Congrats! |

|

| |

|

Veteran

Posts: 141

Location: Simi Valley, CA | Nathan, You are getting quite a fleet of Mopars. The More the Merrier! I'm just playing with my 2(48 Plymouth & 55 Dodge CRL). Hope to see one of your fleet cars at Bobs some Friday night.

Have Fun!

Ernie |

|

| |

|

Expert

Posts: 4042

Location: Connecticut | Is the rear window gasket available ? Otherwise, that'll be a tough nut to find. Your car's twin lives in eastern CT. Ron

(56 Plymouth Amston CT 002 xs.jpg) (56 Plymouth Amston CT 002 xs.jpg)

Attachments

----------------

56 Plymouth Amston CT 002 xs.jpg (451KB - 405 downloads) 56 Plymouth Amston CT 002 xs.jpg (451KB - 405 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Thanks Sid & Ernie. I changed jobs so I no longer work down by Bob's Big Boy. I've been holed up due to the little coronas too, but I'll have to make a point of going down there sometime. I need to show off my Savoy with all the work I've put into it.

Ron, the gaskets are available from Steele Rubber. https://www.steelerubber.com/rear-window-gasket-70-3038-81 They support the '55-'56 years a lot more than the '57-'61 for some reason. Great looking car there. Do you know the owner? I was really surprised to find out today that Eggshell White & Briar Rose were not the original colors of my car. It was originally Jet Black & Briar Rose. I noticed a couple of scratches in the white paint revealing black underneath it too. This car was built in Los Angeles. The tag reads:

SG:1, M3:4, M6:1, M8:3, M9:3

SCHED: 1027 (October 27, 1955)

NO: 3267

MODEL: P293 ('56 Belvedere)

BT: 866 (V8 2dr hardtop)

PT: 680 (Briar Rose body, Jet Black roof/Sport tone)

TR: 510 (Rose vinyl & black/white Aztec patterned cloth)

(56Belvy Body Tag.jpg) (56Belvy Body Tag.jpg)

Attachments

----------------

56Belvy Body Tag.jpg (148KB - 407 downloads) 56Belvy Body Tag.jpg (148KB - 407 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

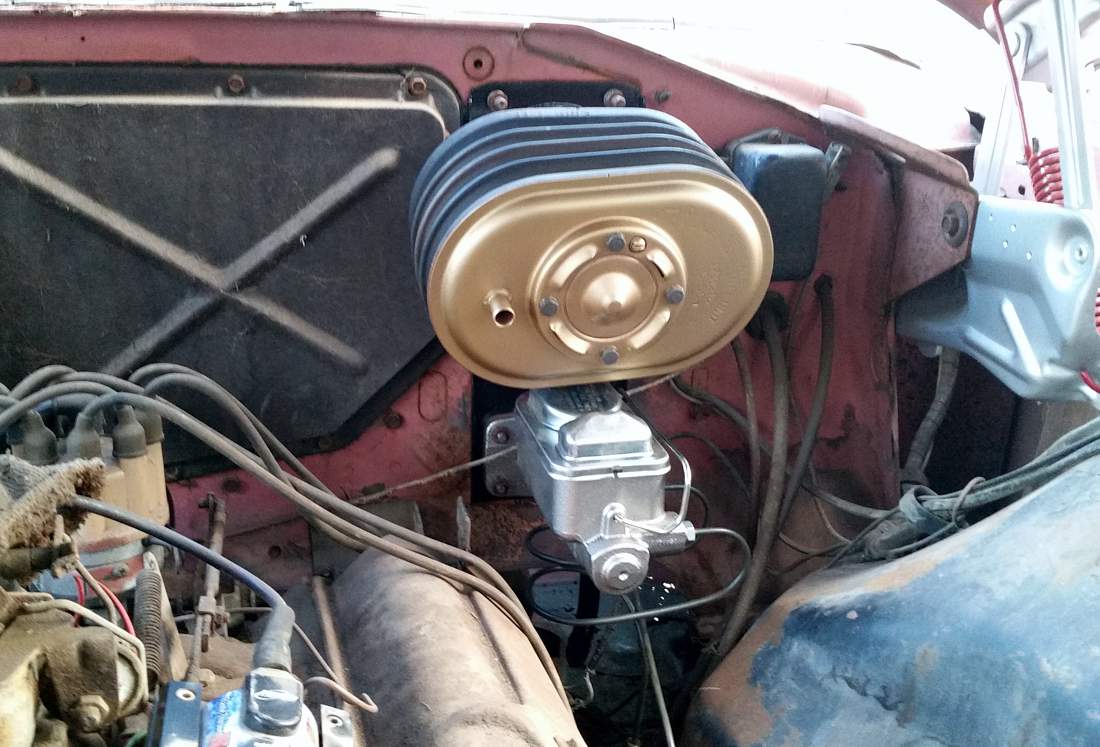

Location: So. Cal | Notice the black inner fenders of a Los Angeles car. It also has the Jubilee trumpet horns that the LA plant used. The 277 motor still has its correct, yellow painted 2bbl air cleaner.  I'm gonna try to swap out the 2bbl setup for a 4bbl intake if I can get my hands on one. Or I might try converting this one to a 4bbl. I'm not a fan of the original 2bbl carbs. I'm gonna try to swap out the 2bbl setup for a 4bbl intake if I can get my hands on one. Or I might try converting this one to a 4bbl. I'm not a fan of the original 2bbl carbs.

Does anyone know if the wedge under this clock is a factory part? It makes a lot of sense to position it to read better on the Plymouth dash, but most of the ones I have seen in other cars didn't have it. Am I to assume that the other cars didn't originally come with this accessory?

Edited by Powerflite 2020-08-18 2:07 AM

(56Belvy Engine.jpg) (56Belvy Engine.jpg)

(56Belvy Dash Clock.jpg) (56Belvy Dash Clock.jpg)

Attachments

----------------

56Belvy Engine.jpg (193KB - 418 downloads) 56Belvy Engine.jpg (193KB - 418 downloads)

56Belvy Dash Clock.jpg (118KB - 411 downloads) 56Belvy Dash Clock.jpg (118KB - 411 downloads)

|

|

| |

|

Elite Veteran

Posts: 655

Location: Finland | Wow that looks like a nice find. Where do you get all that energy Nathan...it is amazing... |

|

| |

|

Expert

Posts: 4042

Location: Connecticut | Steele : For a while, they seemed gung-ho to reproduce anything as long as there was a good original that they could use for a mold. But they seem to have shifted gears. Now they just want to mold gaskets that will be big sellers, like F-o-r-d or C-h-e-v-y stuff. I offered them an original W453 windshield gasket that they could use. They seemed less than interested in doing the job. Plymouth: Yes, I know the owner. I worked on this car for him, mostly doing electricals. Haven't spoken to him in a few years. Ron |

|

| |

|

Expert

Posts: 3967

Location: DFW, TX | Awesome car! One of the first FL cars I had a chance to look at up close, when I was about 10 years old, was a '56 Belvedere basically identical to this car except it was a 4-door hardtop. I was mesmerized by that pattern in the side trim!

I think you're right, it won't take a lot of effort to get this one cleaned up and driving. Looks like a fun project! |

|

| |

|

Expert 5K+

Posts: 9910

Location: Lower Mainland BC | Powerflite - 2020-08-17 10:50 PMI was really surprised to find out today that Eggshell White & Briar Rose were not the original colors of my car. It was originally Jet Black & Briar Rose. I noticed a couple of scratches in the white paint revealing black underneath it too.

PT: 680 (Briar Rose body, Jet Black roof/Sport tone)

TR: 510 (Rose vinyl & black/white Aztec patterned cloth)

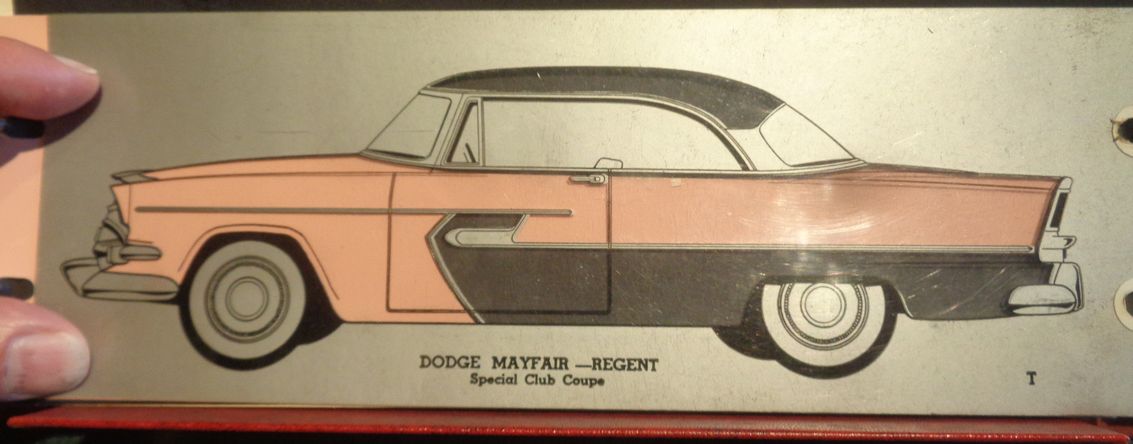

So something like this (using the 1956 Canadian Dodge/Desoto dealer book):

(MockUpOfNathans680PaintCode56Belvedere2drHT.jpg) (MockUpOfNathans680PaintCode56Belvedere2drHT.jpg)

Attachments

----------------

MockUpOfNathans680PaintCode56Belvedere2drHT.jpg (80KB - 414 downloads) MockUpOfNathans680PaintCode56Belvedere2drHT.jpg (80KB - 414 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Ralf: Thanks, I have more time now with the work from home order so I am taking advantage of it. But the sweltering heat right now isn't helping me. Hopefully it'll pass soon.

Ron: You would think Steele would be interested in making a gasket for the Christine cars. Those things are extremely popular. Just goes to show they haven't got a clue.

Danny: Thanks, yeah, back in the early '80s, I fell in love with the '57 Chrysler but never was able to get my hands on one until much later. But in 2001 when I started looking for a different car to put my hemi motor into, I saw a black/white '56 Belvedere and really loved it. I eventually settled for my Savoy, but the "monkey knuckle" or "snail's trail" design as my wife calls it, is really good looking and I sometimes regretted going with the much more plain Savoy.

Dave: That's pretty close, but this is much closer.  I wish I could flatten out these transparencies better. I'm thinking the black is more striking from this comparison, but I'll let my wife decide which we will go with in the long run. Temporarily, it will stay white. I wish I could flatten out these transparencies better. I'm thinking the black is more striking from this comparison, but I'll let my wife decide which we will go with in the long run. Temporarily, it will stay white.

Edited by Powerflite 2020-08-18 2:02 PM

(56Belv Rose-Black.jpg) (56Belv Rose-Black.jpg)

(56Belv Rose-White.jpg) (56Belv Rose-White.jpg)

Attachments

----------------

56Belv Rose-Black.jpg (129KB - 414 downloads) 56Belv Rose-Black.jpg (129KB - 414 downloads)

56Belv Rose-White.jpg (116KB - 404 downloads) 56Belv Rose-White.jpg (116KB - 404 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I think I found the adapter wedge for the dash clock. It's odd that they don't list it for 1955 as well though. Was a clock not an option on the '55 Plymouth? But I also can't find any of the dash clocks for '55-'56 applications listed except the '55 Chrysler, and it's in a completely different section of the parts catalog. None of the others are listed in either location. Weird.

(55-56 Plymouth Dash Clock Adapter.jpg) (55-56 Plymouth Dash Clock Adapter.jpg)

Attachments

----------------

55-56 Plymouth Dash Clock Adapter.jpg (113KB - 404 downloads) 55-56 Plymouth Dash Clock Adapter.jpg (113KB - 404 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | The roof rail trim on this car confused me at first. the doors didn't shut right because the vent window smacked into the roofrail trim. Weird. Then I checked out the Fury and found that the roofrail trim is meant to rotate up out of the way when the door is opened. That allows the window & vent frame enough room to fit underneath the trim. As the door is closed, it rotates the trim downward, making a better seal over the door glass. There are some springs under the trim that facilitate this. Once I loosened up the trim by rotating it a couple of times, it worked great. Pretty wild. Notice also the difference in drip rail trim between the two of them.

Edited by Powerflite 2020-08-20 2:35 AM

(56 Belv Roofrail Trim.jpg) (56 Belv Roofrail Trim.jpg)

(56Fury Roofrail Trim.jpg) (56Fury Roofrail Trim.jpg)

Attachments

----------------

56 Belv Roofrail Trim.jpg (107KB - 405 downloads) 56 Belv Roofrail Trim.jpg (107KB - 405 downloads)

56Fury Roofrail Trim.jpg (98KB - 410 downloads) 56Fury Roofrail Trim.jpg (98KB - 410 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

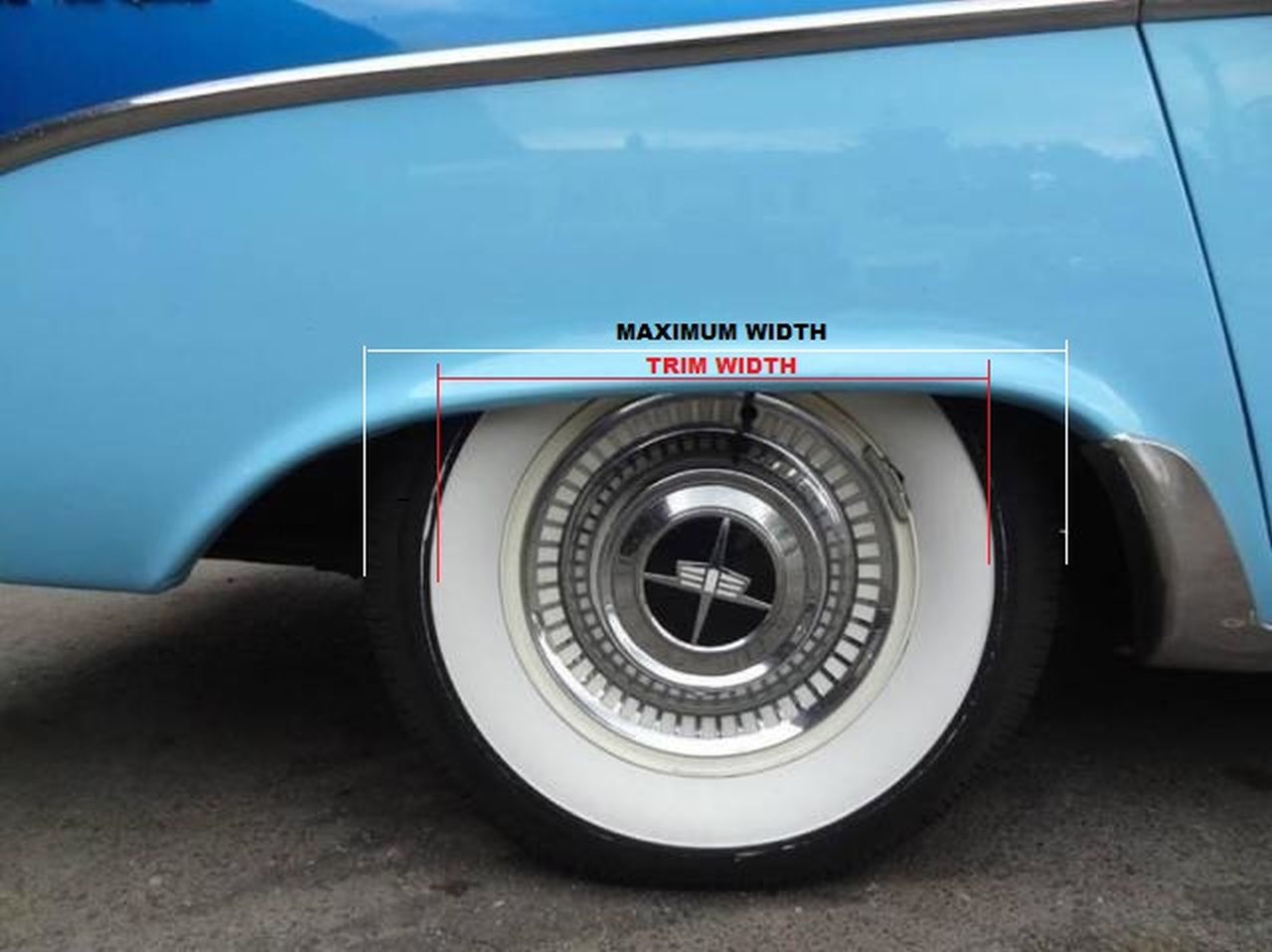

Location: So. Cal | The wheels are painted with these white lines on them. Underneath the pink is a bright turquoise. Anyone know if this is a factory style paint?

(56 Belv Wheels.jpg) (56 Belv Wheels.jpg)

Attachments

----------------

56 Belv Wheels.jpg (188KB - 408 downloads) 56 Belv Wheels.jpg (188KB - 408 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Got this picture of a factory clock in a '55 Belvedere. Apparently a different housing design than the '56 clock and so it doesn't need the wedge underneath it. Looks like a white face with red hands. The '56 Plymouth clock uses a black face with red hands.

(1955 Belvy Dash Clock.jpg) (1955 Belvy Dash Clock.jpg)

Attachments

----------------

1955 Belvy Dash Clock.jpg (60KB - 405 downloads) 1955 Belvy Dash Clock.jpg (60KB - 405 downloads)

|

|

| |

|

Expert

Posts: 1895

| .

It’s a great bargain Nathan!

Returning to the old thread – LA-built cars:

http://www.forwardlook.net/forums/forums/thread-view.asp?tid=67614&...

I guess option M3 = 4 = 424 = Full Dress Trim: Windshield Upper Moulding and Drip Moulding that you describing above…

(M3 = 5 = 425 = Drip Moulding only)

(cowl tag.jpg) (cowl tag.jpg)

(56 codes.jpg) (56 codes.jpg)

Attachments

----------------

cowl tag.jpg (148KB - 407 downloads) cowl tag.jpg (148KB - 407 downloads)

56 codes.jpg (136KB - 407 downloads) 56 codes.jpg (136KB - 407 downloads)

|

|

| |

|

Expert

Posts: 1895

| .

And (or) M6=1=451; Is it an electric clock? |

|

| |

|

Extreme Veteran

Posts: 403

Location: California | Powerflite - 2020-08-20 2:32 AM

The roof rail trim on this car confused me at first. the doors didn't shut right because the vent window smacked into the roofrail trim. Weird. Then I checked out the Fury and found that the roofrail trim is meant to rotate up out of the way when the door is opened. That allows the window & vent frame enough room to fit underneath the trim. As the door is closed, it rotates the trim downward, making a better seal over the door glass. There are some springs under the trim that facilitate this. Once I loosened up the trim by rotating it a couple of times, it worked great. Pretty wild. Notice also the difference in drip rail trim between the two of them.

Wow! That’s pretty neat! I had no idea the 1956’s had that feature. This must have been found on hardtops only,right?

Was the drip rail trim unique to the fury,or did they switch to that style later in production? |

|

| |

|

Extreme Veteran

Posts: 403

Location: California | Also meant to ask,did Chrysler refer to the optional steering wheel as the “Hollywood” wheel? If not what was it called and how did it come to get the nickname “Hollywood”? |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | M6=1 seems plausible to indicate the electric clock. This is the only one I have that came with it, so I have no way to verify it though.

The different drip rail trim is just an option that could be ordered or not. As Igor indicated, the Rose Belvedere came with the optional wide roof trim, but the Fury didn't. I think it was available on the Fury too though.

The steering wheel is the optional "plastic" wheel, which when it first came out in 1955, was called the "Hollywood" wheel, I guess because plastic was associated with Hollywood for some reason. But after 1956, the optional plastic wheel became much more common and no longer carried the Hollywood name. And the Hollywood wheel was standard on the '56 Fury, but optional on everything else. However it's a standard option for all my cars

Edited by Powerflite 2020-08-25 4:33 PM

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I decided to work on this car now since putting the rear window into it is a high priority and there's a good chance I can get this motor running...we'll see. The floor mat in it is really cool, and looks like it was originally a nice pink color (from the backside) that has faded to the white you now see. It's extremely brittle now so no real chance of even getting it out without breaking it all apart. One of these rubber floor mats completely rusted out the floor in the yellow Fury. Hopefully this one hasn't suffered the same fate.

(56Belv Pink Floor Mat.jpg) (56Belv Pink Floor Mat.jpg)

Attachments

----------------

56Belv Pink Floor Mat.jpg (205KB - 291 downloads) 56Belv Pink Floor Mat.jpg (205KB - 291 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Check out this early version of a PCV valve. It looks like the original down draft tube that has been capped off and tapped at the top of it to accept an old version of a one-way restrictor valve, and leads to two ports tapped into the top of the manifold. Pretty cool, but I'm not going to keep it like this.

(56Belv Old PCV.jpg) (56Belv Old PCV.jpg)

Attachments

----------------

56Belv Old PCV.jpg (173KB - 301 downloads) 56Belv Old PCV.jpg (173KB - 301 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | My first priority on this car is to replace the broken rear window and to clean it out. There was an enormous amount of dirt and misc. debri under the rear seat, that had collected there & gotten wet from the missing window, but it hadn't rusted the rear floor yet, so that was really nice. I pulled the rear window trim & the remaining rubber gasket from the car. The small outside trim is what holds it all together. It is bolted to the car all along its length. The last bolt you have to access underneath the upper quarter interior trim panel, shown in the picture sitting on the package tray. I recommend that you either eliminate that last bolt or else cut it down shorter because removing the trim with that stud extended is very difficult to do without either first removing the extremely painful belt trim molding under the quarter glass, or else bending the trim a little. That belt trim molding is by far the hardest thing to remove on the car because it requires removing the rear window & regulator assemblies, which is non-trivial, especially when things become rusted. Not to mention the headache of trying to adjust it properly after putting it back together. Cutting that last stud shorter, or eliminating it entirely will make it much easier to remove the rear window trim without having to deal with that belt trim molding or bending things.

The larger trim near the rubber gasket is clamped in place at the bottom by the small trim, but also inserts into the rubber gasket at the top. But otherwise, it has no clips or other means to hold it in place. There are 2 screws that hold the decorative C-pillar trim on at the bottom, and those screws are always rusted out. No hope of being able to unscrew them, even with heat from a torch because the heads are almost non-existent. The factory really should have used stainless screws here and that's what I'll do after I drill out the remains of the old ones. There is also a clip at the top that the trim clips onto, that you can see in the pictures. Quite a bit of rust had developed under all this trim so it's going to be a lot of fun to fix all of this. I just hope I don't mess up the original paint too much so I can get it back together without it looking too badly from the experience.

You can see from the pictures that the roof was originally painted black.

Edited by Powerflite 2021-02-20 11:53 AM

(56Belv Rear Channel Rot Right.jpg) (56Belv Rear Channel Rot Right.jpg)

(56Belv Rear Channel Rot Left.jpg) (56Belv Rear Channel Rot Left.jpg)

Attachments

----------------

56Belv Rear Channel Rot Right.jpg (129KB - 288 downloads) 56Belv Rear Channel Rot Right.jpg (129KB - 288 downloads)

56Belv Rear Channel Rot Left.jpg (145KB - 290 downloads) 56Belv Rear Channel Rot Left.jpg (145KB - 290 downloads)

|

|

| |

|

Elite Veteran

Posts: 655

Location: Finland | Not too badly rusty but some stitching it sure needs...the belt line molding between side glass and back glass is always a pain whatever car it is. Sometimes I have

made a special clip bolted to the rear quarter so I have been able to slide on that darned trim piece...trial and error is the way... |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Yeah Ralf, this car doesn't have much rust. It does have some issues from having the window missing for so long, but fortunately, not terrible. Using a custom clip to hold on that molding is a good idea. When I tear the cars apart for paint, I'll have to give that a try.

I took a first pass at welding in all the rust sections. I welded in appropriately bent small washers to fill in the larger holes, and that worked out really well. I'll need to do another pass to address some of the spots I missed, but should get it done after that. I scuffed the pink paint in a couple of places, but not bad. This will not all hide under the trim of course, but just trying to keep the damage zone to a minimum. On the left inner edge, I dug into an old brazing job. I assume that was done by the factory as there doesn't appear to be any repairs made to the car and the lead seam is still in place, but who knows. There was also a large hole in the trunk trough for some reason. I'm sure that had been leaking water into the trunk for quite a while and created a small rust section there. I welded that up as well to prevent any future issues.

Edited by Powerflite 2021-02-21 10:42 AM

(56Belv Rear Channel Welded Right.jpg) (56Belv Rear Channel Welded Right.jpg)

(56Belv Rear Channel Welded Left.jpg) (56Belv Rear Channel Welded Left.jpg)

Attachments

----------------

56Belv Rear Channel Welded Right.jpg (138KB - 293 downloads) 56Belv Rear Channel Welded Right.jpg (138KB - 293 downloads)

56Belv Rear Channel Welded Left.jpg (135KB - 283 downloads) 56Belv Rear Channel Welded Left.jpg (135KB - 283 downloads)

|

|

| |

|

Expert 5K+

Posts: 9910

Location: Lower Mainland BC | .

Nathan: Nice work again. It sure would be nice to be able to weld and fix things like that when you have to.

Could you explain, maybe with more photos (?), how the stainless sail panel was attached to the C pillar? I might want to swap in nicer ones on my 56 Dodge.

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Dave, 4dr sedan trim is completely different from 2dr hardtop trim. Nothing is the same on it, so any instructions I give won't translate to your car. |

|

| |

|

Extreme Veteran

Posts: 329

Location: Claremore, Okla. | I have a good set of bumper wings & back glass for 56 h/t if you know anyone interested |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I might be interested in the glass if I end up breaking this one.  |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I finished painting the window area and installed the window yesterday. I haven't finished installing the lower-most trim yet. I have to get into the trunk and tighten the nuts onto it. My hands are quite sore today from all the man-handling it takes to get the window installed and the trim installed afterward. The car came with an extra used rubber that was in decent shape - nice and pliable with only one crack in it. So I decided to use it instead of purchasing a new one. This time I lubed up the rubber quite a bit to make the process easier, but it still wasn't a lot of fun. At least this way, there was no danger to breaking the glass trying to get it in.

That upper trim piece is a lot of fun to install. It took me probably a dozen tries before I got it to go in. I had to lube up the lip that it inserts into really well, and clean & lube up the trim too, so it wasn't dirty or dry. The method that eventually worked for me was to install the trim at the center first and then work my way to each side afterward. The final push required is at each corner to pop it into the groove after the ends are in place. The lower trim next to the rubber didn't give me any trouble, but the lower-outer trim did for some reason. I had a hard time re-inserting that trim underneath the quarter belt molding far enough. It's just really hard to push it further inward. But I think everything is where it needs to be now and I am glad to have it mostly done. I'm happy I don't have to install any more glass for a while....until I get back to the New Yorker's rear window.

(56Belv Rear Window Installed Left.jpg) (56Belv Rear Window Installed Left.jpg)

(56Belv Rear Window Installed Right.jpg) (56Belv Rear Window Installed Right.jpg)

Attachments

----------------

56Belv Rear Window Installed Left.jpg (124KB - 293 downloads) 56Belv Rear Window Installed Left.jpg (124KB - 293 downloads)

56Belv Rear Window Installed Right.jpg (115KB - 289 downloads) 56Belv Rear Window Installed Right.jpg (115KB - 289 downloads)

|

|

| |

|

Elite Veteran

Posts: 655

Location: Finland | The car looks like a million times nicer now...I agree that the glass work is so not funny...especially the upper molding...ouch... |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Yes, having the glass in and the rust around the rear window welded up is a big relief. It no longer looks like an abandoned car sitting there, and that expensive window is in place and un-cracked. The seats in this car still have the original fabrics & clear plastic seat covers on them. The lower rear cushion was covered in a thick layer of dirt/mud that mostly saved it from being destroyed by the damaging UV rays. It's seat cover is still soft and supple and could be used as is, although it's quite stained and more brown than it should be. The upper cushion wasn't so lucky. It not only had lots of UV hitting it, but was also fully exposed out in the weather the whole time. That one needs a complete redo, but the springs in it look OK, so that's good.

(56Belv Rear Seats.jpg) (56Belv Rear Seats.jpg)

Attachments

----------------

56Belv Rear Seats.jpg (248KB - 293 downloads) 56Belv Rear Seats.jpg (248KB - 293 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I purchased these new springs for the rotating trim above the door windows from a guy "stellarrestorations" out of Kansas on Ebay. I purchased enough for all three of my '56 Plymouth 2dr hardtops.

https://www.ebay.com/itm/1955-1956-Dodge-Plymouth-2-door-hardtop-win...

They used 2 different styles that had different ways of mounting to the trim. There was an early style with 2 loops in the front spring and single loops in the rear, and a later style that just used single loop springs at all four locations. It seems that the later style tends to work better and last longer before breaking. This car is an early build in October 1955 and uses the 2 loop version. My yellow Fury is also an early build car probably from January or February of '56 and also uses the 2 loop version. The white Fury is a later build, probably from March or April of '56 and uses the single loops on each position. None of the 2 loop springs are still functioning, but many of the single loop springs are still working well. Hopefully, these stainless springs should solve the problems though.

(56 Plym 2dr Hardtop Trim Springs.jpg) (56 Plym 2dr Hardtop Trim Springs.jpg)

Attachments

----------------

56 Plym 2dr Hardtop Trim Springs.jpg (136KB - 277 downloads) 56 Plym 2dr Hardtop Trim Springs.jpg (136KB - 277 downloads)

|

|

| |

|

Expert

Posts: 4042

Location: Connecticut | Powerflite - 2021-03-02 12:33 AM I purchased these new springs for the rotating trim above the door windows from a guy "stellarrestorations" out of Kansas on Ebay. Stellarrestorations is Tim Bowers, who owns a shop by the same name. He has done some concours-winning restorations. Most notably a 56 Adventurer. He's very active in the Desoto club and is a good guy. Ron |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Thanks for the info. His clips look like they should work out well, and I'm grateful I don't have to make them!

Everywhere I look on this car, it looks to be in very original condition. It seems to have been mostly untouched since it was purchased. I've never seen a coil housing like this before. It's an AC Delco, but the housing is a very old style.

(56Belv Coil.jpg) (56Belv Coil.jpg)

Attachments

----------------

56Belv Coil.jpg (110KB - 281 downloads) 56Belv Coil.jpg (110KB - 281 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

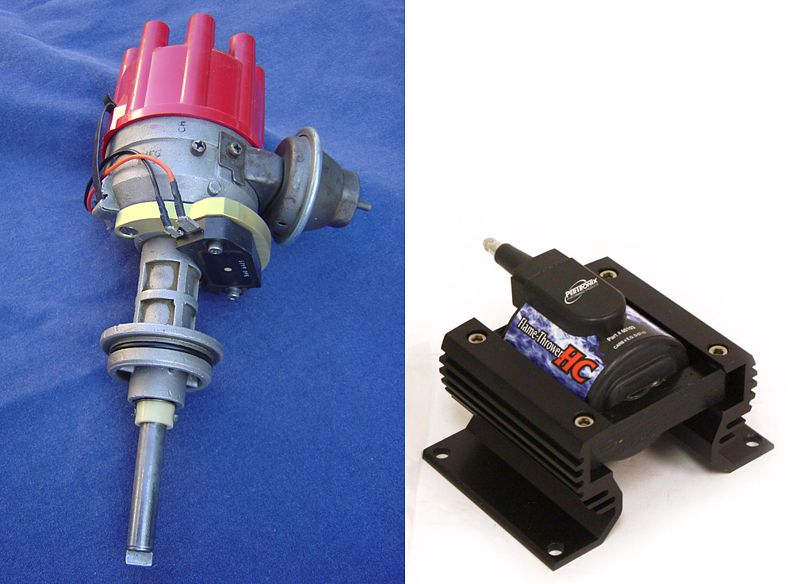

Location: So. Cal | I replaced the distributor with an electronic one, an HEI module, and a powerful E-core coil, gave it some fresh oil and gas in the carb, and put a battery in it for the first time. The park lights work and the headlights worked briefly before dying. Not sure what happened with them, if the elements burned up or if there is a problem with the switch. One light on the dash works, the ignition key light. Nothing works at the back of the car. But the good thing is this car came with an ignition key! Yay! No need to pull the switch and get one made for it.

I tried to start it and the starter & relay all work nicely, but it wouldn't start. So I retarded it from where it was set with the old distributor. That didn't work; as a loud bang erupted from the exhaust and scared me because of how big of a bang it was. Apparently the wrong direction!  So I advanced it and it still did nothing. I advanced it more and more and more, and then it finally fired up! Seems to run quite well so far! I'll have to go through everything to get coolant and probably a rebuilt fuel pump on it now. Running is always better than not running! So I advanced it and it still did nothing. I advanced it more and more and more, and then it finally fired up! Seems to run quite well so far! I'll have to go through everything to get coolant and probably a rebuilt fuel pump on it now. Running is always better than not running!

(56Belv Is Alive!.jpg) (56Belv Is Alive!.jpg)

Attachments

----------------

56Belv Is Alive!.jpg (140KB - 284 downloads) 56Belv Is Alive!.jpg (140KB - 284 downloads)

|

|

| |

|

Expert 5K+

Posts: 9910

Location: Lower Mainland BC | .

Congrats Nathan. Good job.

|

|

| |

|

Elite Veteran

Posts: 655

Location: Finland | Those moments are exciting! A bang or two and then it comes some smoke and if one is really blessed it might move in one or both directions...progress.. |

|

| |

|

Expert 5K+

Posts: 7403

Location: northern germany | I still think, this is one of the nicest FL cars ever presented here. Love it. |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Thanks guys. Hopefully when I get it to a point that I can drive it, the motor will work well enough to use for a while.

Since this car will be my youngest daughter's, I wanted to convert it to power brakes & power steering to make it easier for her to drive it. So I purchased a power brake pedal assembly from the trunk of a '56 Dodge at BigM's the last time I was there. It had a gray pedal on it and was quite weathered from sitting in the open trunk for many years. Now that I am cleaning it up, I noticed that the rubber on the back of it was pink colored. So I scrubbed off the top surface to find that the whole pedal is actually a pink color. I've never heard of a pink colored pedal for these cars before. Does anyone know about it? Would that have been used on a Le Femme possibly? Anyway, it seems fitting to use on this car, given its color scheme, but I don't have a matching accelerator pedal, unfortunately.

I've never had a classic car that still had it's original fuel hose, but this one does. It looked good too, until I touched it and it broke all apart. It's a hose similar in design to the brake hose at the master cylinder. Would be cool if you could get a new replacement for it, but maybe not worth the trouble.

(56Belv Pink Brake Pedal.jpg) (56Belv Pink Brake Pedal.jpg)

(56Belv Fuel Hose.jpg) (56Belv Fuel Hose.jpg)

Attachments

----------------

56Belv Pink Brake Pedal.jpg (125KB - 268 downloads) 56Belv Pink Brake Pedal.jpg (125KB - 268 downloads)

56Belv Fuel Hose.jpg (199KB - 275 downloads) 56Belv Fuel Hose.jpg (199KB - 275 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I did something really stupid. Got this new pedal assembly all cleaned up and painted, and then realized I forgot to weld the brake switch mount to it. I'll also need to grind a spot to get a ground connection.  Not smart. Oh well, just get 'er done, right? This thing was a lot harder to take apart than it should have been, mostly because it had been sitting outside for quite a while. The brake rod was practically seized to the pin so it required heat to get it apart and there isn't a great way to push on it because of its location. Putting it back together isn't real easy if you get paint in the bushings either, but fortunately its easy to clean out afterward. Not smart. Oh well, just get 'er done, right? This thing was a lot harder to take apart than it should have been, mostly because it had been sitting outside for quite a while. The brake rod was practically seized to the pin so it required heat to get it apart and there isn't a great way to push on it because of its location. Putting it back together isn't real easy if you get paint in the bushings either, but fortunately its easy to clean out afterward.

Edited by Powerflite 2021-03-12 4:10 PM

(56Belv Pedal Assembly Painted.jpg) (56Belv Pedal Assembly Painted.jpg)

Attachments

----------------

56Belv Pedal Assembly Painted.jpg (270KB - 270 downloads) 56Belv Pedal Assembly Painted.jpg (270KB - 270 downloads)

|

|

| |

|

Member

Posts: 30

| Man,it looks brand new,well done ! That pink pedal looks so special,but cool..like it was made for your Belvedere... |

|

| |

|

Expert 5K+

Posts: 9910

Location: Lower Mainland BC | .

Too bad about the miss Nathan. I know you will fix it real well.

Question: What paint did you use on the pedal bracket? I need to paint one of mine very soon.

|

|

| |

|

Member

Posts: 30

| Just wonder if you're going for a disc brake conversion on this one ,and if so,what kind ? Earlier on this tread,there are some pictures of the dash clock,I have two of them in my parts pile somewhere,and one of them is for a 56' DeSoto.They came with white face gauges,and so is my clock...the other one is for 55/56 Plymouth's,and has the black background..

I'm thinking..you have the 56' Fury,Belvedere and Savoy..but no Plaza..? A 2 door wagon would be nice,since I probably will need some inpiration from someone like you,with your ability to get things done for getting somewhere with my 55' wagon..he,he |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I was told by DepsilonD & Danny that the pedal was used on some '56 Dodge power brake pedals to highlight the power feature more, but is quite rare. Not sure if it was used late in the year or early, or at a specific factory, or ??

Dave, I used a bronze color on the bracket, but it comes out as more of a gray. I misted over it with a light pewter color which gave it a really cool metal textured look to it. You can kind of see it on the bottom flange a little bit, but the effect is mostly lost in the photo.

Geir, I will convert it to use the large 12" disc conversion from AAJ that I used on my white Fury. They say that you must use '56 Dodge hubs with that, but I modify the brackets to make it work well with the Plymouth hubs. There's quite a bit of modification required so it's not for the faint of heart. But it does work well on my Fury. If you are interested in doing the same thing, I can go over it in more detail on this build, but you can refer to my Fury page to see what's there first. They also sell a smaller 11" version that doesn't require modifications like that, but does require you to tap your spindle, which must be done very -straight- to work. I used that one on my Savoy before the 12" version became available. I think there are other 11" options for these cars too, like from Rusty Hope and other places, but I haven't tried them.

The DeSoto clocks are quite common, but the Plymouth clocks are more rare. If you get a chance, post a picture of your Plymouth clock. They used a number of different configurations, especially on the '55's so it would be neat to see what you have. Yep, I almost have the whole lineup, except for the Plaza now. But I think I have enough of them for the time being.  What's funny is I purchased yet another car last year that I still haven't received yet due to covid restrictions. Hopefully I can get it in soon, but it isn't a Plymouth. What's funny is I purchased yet another car last year that I still haven't received yet due to covid restrictions. Hopefully I can get it in soon, but it isn't a Plymouth. |

|

| |

|

Elite Veteran

Posts: 655

Location: Finland | The color of the pedal assembly for sure is special...I wonder what the coming soon car is ...I don`t think it is a chevy.... |

|

| |

|

Member

Posts: 30

| Ok Nathan,thanks for the info. Thing is,I installed the AAJ 11" set two years ago,and , the installation was a real challenge,expecially when you live in a metric country. I can't recall reading on their website you need to tach weld,tapping 5/8 UNF treads and reaming larger holes in the steering arms..? In addition comes the grinding on the hubs..well, it was my fault,I guess,I took all the old parts off my car,before unpacking the adapters,and like most men,I didn't bother to read the instructions first.The car was in winter storage with old wooden floors,so no power tools allowed,and no tach welding,of course. Naturally.I couldn't assemble the car again,get out in the snow,and pull it home too my " weld safe " garage,so that ment hand filing down the hubs,and tach weld the nuts on the backside of the brake shields instead of the hubs ( cause I could take those home ) Since the installation,I've spent hours trying to get a firm pedal and good brake preformance,but just can't figure out what the problem is to why I can't..

Will try and find the clock,but not shure how to link pictures to this site ?

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal |  No Ralf, it's not a Chevy. No Ralf, it's not a Chevy.

Geir, you need to isolate the problem to figure out where it's coming from. Try clamping off the rear brake hose and see if your problem is fixed. If so, you know the problem is in the rear brakes. A very common problem with these conversions is that the plug used in the brake junction leaks air. Those plugs are garbage. If you analyze the plug fitting, you'll see that it's amazing it seals at all. And if you tighten it hard, it will likely ruin your brass junction block. I highly recommend that you make your own plug by using a brake line and welding & brazing it shut instead like what I do in this picture.

56D500boy has posted a tutorial on how to upload pictures. http://www.forwardlook.net/forums/forums/thread-view.asp?tid=64340

pictures must not exceed 250Kb, and must be .jpg, not .jpeg.

Edited by Powerflite 2021-03-14 4:49 PM

(56Fury White Brake Plug.jpg) (56Fury White Brake Plug.jpg)

Attachments

----------------

56Fury White Brake Plug.jpg (111KB - 278 downloads) 56Fury White Brake Plug.jpg (111KB - 278 downloads)

|

|

| |

|

Member

Posts: 30

| Nathan,thanks for valuable tips and info,I will swap that plug ASP. I would never have thought that plug might be the problem.. |

|

| |

|

Veteran

Posts: 148

Location: Mandurah, Western Australia | Hey Nathan, good to see you got the motor running, they seem to be unbreakable. Would love to hear it running. My 55 has been converted to 12v and has Pertronix ignition, fires up great despite being a bit tired, once I figured out how to get fuel to the carby. It seems to boil away when left a day or two and a new fuel pump didnt help, so put in an electric "booster" used only at startup.

I had no problem replacing that flexible fuel line, pretty sure I got it from Bernbaum, but there are a few different ones listed and he doesnt show pics.

Love the pink pedal!. |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Thanks Jim. I'm not very good with videos, but I'll give it a shot once I get it closer to being driveable. I did get a replacement fuel line from MoparPro, we'll see how it goes.

The home-made PCV setup that was on here was leaking terribly. The hoses were bad, one of the connections was loose, and the restrictor valve wasn't sealed well. So I intended to take it all out and replace it with some steel lines. But I couldn't do that because the connections to the intake aren't threaded. They are just jammed in there. I didn't want to thread the intake now and risk getting metal in the motor so I used some JB weld and epoxied them back in and replaced valve and the hoses. It's ugly, I know, but it'll have to do for now. I also cleaned up the hood hinges & sprayed the new springs from Ebay an appropriate color.

(56Belv Ugly PCV.jpg) (56Belv Ugly PCV.jpg)

Attachments

----------------

56Belv Ugly PCV.jpg (169KB - 289 downloads) 56Belv Ugly PCV.jpg (169KB - 289 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I also cleaned up the floors yesterday to see where they stand. They aren't as good as I had hoped they would be, unfortunately. The right side is worse than the left, and has rusted through multiple layers into the top of the rocker. Thankfully, the rear floors are pretty clean. Because there aren't really good replacement panels available, I will likely patch this with multiple small panels to get it looking right afterward. That's required anyway to get all the layers done right at the hole above the rocker. The driver's side should be a lot easier to do. Because I am determined to get this car drive-able, I will go ahead and do the floor repair work now.

(56Belv Floor Rust.jpg) (56Belv Floor Rust.jpg)

Attachments

----------------

56Belv Floor Rust.jpg (141KB - 286 downloads) 56Belv Floor Rust.jpg (141KB - 286 downloads)

|

|

| |

|

Expert 5K+

Posts: 9910

Location: Lower Mainland BC | .

Nathan: Did you add the newly painted hood springs to the newly cleaned and painted hood hinges when the hinges were off the car? If so, how did you stretch the spring the needed 1.5" or so to do that? (I'm going to work on my second set of hinges and springs (all off the car) and would appreciate a method that is simpler than my Sven-inspired threaded hood spring "jack"

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Yep, stick the flat flange end of the hinge in a vice (with cloth so it doesn't ruin the paint), put the top end of the spring in position on the hinge, put a thick wire like a clothes hanger on the bottom part of the spring, wear heavy gloves, put your foot on the vice for leverage, and pull the wire to bring the spring to the proper position. It's amazing that the wire (& gloves) allows you to pull with much more force than you can otherwise apply to it.

I used the same approach to replace the spring on my gold New Yorker without removing the hood nor hinge. I stood on a chair with my knee on the back of the hinge for leverage, and pulled up on the wire to install the upper point of the spring on the hinge. And a similar approach to replace the broken spring on my yellow Fury, but the hood was already removed, so it was easier.

Edited by Powerflite 2021-03-21 2:56 PM

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I found this tag behind both rear arm rest panels. It looks like it would have had more information on it at one point, but these just have the 1554273 part number on them....which I can't find in the '55-'58 catalog. The meaning of LA seems obvious as this car was manufactured in the Los Angeles plant, but I wish I knew what NAFI stood for. National Automotive Fabrics Industry? That's my best guess.

(56Belv Rear Arm Rest Number.jpg) (56Belv Rear Arm Rest Number.jpg)

Attachments

----------------

56Belv Rear Arm Rest Number.jpg (166KB - 284 downloads) 56Belv Rear Arm Rest Number.jpg (166KB - 284 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | The problem with fixing rust is it extends to every layer. You peel back more and more to reveal more problems. But I've figured it will take about 8 patches on the right side with the different layers and 4 or 5 on the left. Would be a lot easier if good replacement panels were available, but oh well.

I cut the main patch from the rear floor of my '57 New Yorker parts car. I used the section which has the two beads extending up onto the tunnel. I had to extend the beads a little after I cut it out, but it was pretty easy with them already formed there. I had to fix the holes in it from removing the under floor brace and modify the bend a little to fit properly. I also had to add the step into the side of it. Since it's relatively small, I was able to add those bends using my vice, and then cleaned up the bends with an elevated anvil. I've got it mostly welded into the floor now, but I've still got to clean it up. Next, I'll patch in the large hole at the top of the rocker & fix the pocket for the body mount.

Edited by Powerflite 2021-03-28 12:21 AM

(56Belv Rt Floor Layers Cut.jpg) (56Belv Rt Floor Layers Cut.jpg)

(56Belv Rt Floor Main Patch.jpg) (56Belv Rt Floor Main Patch.jpg)

Attachments

----------------

56Belv Rt Floor Layers Cut.jpg (196KB - 288 downloads) 56Belv Rt Floor Layers Cut.jpg (196KB - 288 downloads)

56Belv Rt Floor Main Patch.jpg (152KB - 280 downloads) 56Belv Rt Floor Main Patch.jpg (152KB - 280 downloads)

|

|

| |

|

Veteran

Posts: 148

Location: Mandurah, Western Australia | Like Shrek says, they are like onions, they have layers! I had fun doing the sills on my 55 wagon, 4 layers deep around the rear doglegs, was lucky enough to get some sill repair panels bent up by a local trailer fabrication shop for $40. Rebuilding the 29 Plymouth was a breeze by comparison.

(DSC00176.JPG) (DSC00176.JPG)

Attachments

----------------

DSC00176.JPG (246KB - 279 downloads) DSC00176.JPG (246KB - 279 downloads)

|

|

| |

|

Member

Posts: 30

| I've done the exact same job,both sides on my 55' wagon,so I know how difficult and time consuming it is. Luckily I found a very kind guy in Nebraska who sent me lots of panels in better shape from a car he butchered..but,you are moving fast forward Nathan,so you'll get there ! |

|

| |

|

Member

Posts: 18

| Powerflite - 2021-03-07 12:29 AM

I replaced the distributor with an electronic one, an HEI module, and a powerful E-core coil, gave it some fresh oil and gas in the carb, and put a battery in it for the first time.

This caught my attention as I'm working on getting my 56 running again and following your thread, what is the HEI modeul & E-Core coil?

Thanks |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | The later electronic ignition small block distributors are a direct drop in replacement in the '56 Plymouth poly motor. So I use one of them, but couple it with a GM HEI ignition module that I mount to the bottom of the distributor. The remaining 2 connections go to the coil. So no ignition box that I have to mount on my firewall or fender. Works really well and eliminates the required ballast, with an appropriate coil. This 60103 coil from Pertronix has very low .32 ohms primary resistance to provide lots of power. It allows me to open the spark plug gap up to .052", depending on compression ratio. I make and sell the conversions on my website here. http://www.designed2drive.com/

(HEI and Coil.jpg) (HEI and Coil.jpg)

Attachments

----------------

HEI and Coil.jpg (72KB - 275 downloads) HEI and Coil.jpg (72KB - 275 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Thanks Jim and Geir, just got to keep at it to get it done. I welded in the 2nd patch today over the top front of the rocker. That closed it up nicely. Then I cut up a new patch for the outer section of the upper floor and got it spot welded in. It surprised me that the inner metal under that floor was like brand new, unpainted as if it had left the factory yesterday. Kind of odd that it didn't even get a coating of rust on it. I didn't hesitate to put a coat of paint over it before I buttoned it up though.

(56Belv 2nd Patch & Pocket.jpg) (56Belv 2nd Patch & Pocket.jpg)

Attachments

----------------

56Belv 2nd Patch & Pocket.jpg (169KB - 269 downloads) 56Belv 2nd Patch & Pocket.jpg (169KB - 269 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I welded four more patches into the floor. I seem to have started a little patch garden here.  But I feel good about how it's turning out. I'll need to clean up the majority of these welds now before I proceed to repair the vertical kick panel area. So that's what I'll do next. I also need to test fit the sill plate cover afterward to make sure things didn't shift around before I call it good. But I feel good about how it's turning out. I'll need to clean up the majority of these welds now before I proceed to repair the vertical kick panel area. So that's what I'll do next. I also need to test fit the sill plate cover afterward to make sure things didn't shift around before I call it good.

(56Belv Patch Garden.jpg) (56Belv Patch Garden.jpg)

Attachments

----------------

56Belv Patch Garden.jpg (209KB - 266 downloads) 56Belv Patch Garden.jpg (209KB - 266 downloads)

|

|

| |

|

Expert 5K+

Posts: 7403

Location: northern germany | Looks great Nathan. I too always try to save as much of the original sheet metal as possible, that is the only way to do it and the original contours remain. Better than replacing the whole section with a cheap, thin, out of shape repro. |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Yeah, I won't touch those crappy replacement panels. So far off from reality, they are like cartoon versions. But I prefer to have full replacement OE panels rather than having to replace them in parts like this, but since good full panels aren't available to me, this is a good alternative. After these are cleaned up, I'll only need a little more work to finish up the right side of the car. Fortunately, the left is quite a bit better than this side. |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Since I am reattaching the hood, I thought I would make it look a little better. The underhood trim on the front of this car was really rusted out on the left side, but the right side still looked great. Nevertheless, the right side had some deep pitting in places that fortunately hadn't worked their way through the part yet. These chromed trim parts are some of the most susceptible parts on a '55-'56 Plymouth for rust, because the factory just left them with only the thin chrome plating on the backside to protect them. But sitting upside down most of their lives means they catch all sorts of dirt and water in there, left to sit and rust. So even though I'm replacing the rusted trim with an NOS version, I'm painting the backside of it to protect it better. I really should do this to all the pot metal trim parts too. Much of the worst pitting often starts at the backside. I'll clean up any paint that might be visible from the other side after the paint dries, with some acetone.

(56Belv Hood Trim Backside.jpg) (56Belv Hood Trim Backside.jpg)

Attachments

----------------

56Belv Hood Trim Backside.jpg (186KB - 258 downloads) 56Belv Hood Trim Backside.jpg (186KB - 258 downloads)

|

|

| |

|

Veteran

Posts: 148

Location: Mandurah, Western Australia | The 55 has the same hood front side trims and mine were bad. I managed to get used replacements but they cost an arm and a leg to get rechromed as local environmental regulations have put most such services out of business. I painted the inside of mine likewise. Next time I will try and hang out for good user quality chrome parts as am not trying to create a trailer queen.

One problem with this trim is every time it rains or I wash the car, it fills with water that only drains out when I open the hood, usually over me. I wonder if anyone has come up with a solution to this? |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal |  That's how it works alright! Always have to remember to lift the hood to drain it out of there. I agree with rechrome costs. Almost not worth it. I was lucky and managed to pick up some NOS parts, and that's why I am so keen on protecting them. That's how it works alright! Always have to remember to lift the hood to drain it out of there. I agree with rechrome costs. Almost not worth it. I was lucky and managed to pick up some NOS parts, and that's why I am so keen on protecting them.

Amazing how much better the front end of the car looks after a little clean up, and after replacing that rusted chrome strip. I also tested & replaced both headlamps. They were all bad except for the high beam on one of them....which went bad after 7 seconds of testing.  But the headlamps still don't work, so their issue seems to be multi-faceted. I know the wiring works, so I'll have to trace down the problem from the high beam switch to the light switch. But the headlamps still don't work, so their issue seems to be multi-faceted. I know the wiring works, so I'll have to trace down the problem from the high beam switch to the light switch.

Edited by Powerflite 2021-04-16 12:04 PM

(56Belv Frontend Cleaned.jpg) (56Belv Frontend Cleaned.jpg)

Attachments

----------------

56Belv Frontend Cleaned.jpg (213KB - 258 downloads) 56Belv Frontend Cleaned.jpg (213KB - 258 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I did some of the clean up and welded in three more patches to the right side yesterday, two in the vertical section and one at the rear rocker. This should be the last ones required for the right side. It'll probably take a full day to finish cleaning up all the welds and re-weld any holes or low spots in it afterward, before I can move on to the left side. I'll also do a little clean up to the underside & paint it as well, but with the body on the frame, I am limited with what I can do under there. It's nice to see it starting to look like a decent floor again.

(56Belv Right Vertical Patches.jpg) (56Belv Right Vertical Patches.jpg)

(56Belv Right Rear Uppper Rocker Patch.jpg) (56Belv Right Rear Uppper Rocker Patch.jpg)

Attachments

----------------

56Belv Right Vertical Patches.jpg (142KB - 261 downloads) 56Belv Right Vertical Patches.jpg (142KB - 261 downloads)

56Belv Right Rear Uppper Rocker Patch.jpg (205KB - 269 downloads) 56Belv Right Rear Uppper Rocker Patch.jpg (205KB - 269 downloads)

|

|

| |

|

Member

Posts: 30

| Great work Nathan ! You're almost there ! |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Thanks Geir. I haven't had as much time to work on it as I would have liked, but I managed to get most of the clean-up work done on it. I also put in one more patch because there was too much pitting on that section for my liking. I also fixed a couple of small issues on the driver's side rear, in front of the seat, so I could paint a majority of the floor and put the rear seat back into it. After painting, I found a couple of issues that I couldn't see before, so I'll need to touch those up, and I already fixed a couple of issues that need to be cleaned up still. I also need to hammer up the weld area from below in order to properly clean up the visible weld at the lower part of the photo. But definitely coming into the home stretch on the right side repairs. But once I get the rear seat back into it, I think I will concentrate on getting the brakes working & the motor fuel & cooling systems working so that I can make it driveable. I want to have that done so I can easily move it out of the way when I need to before I tear into the driver's side floor issues.

Edited by Powerflite 2021-05-02 12:32 PM

(56Belv Right Floor Primed.jpg) (56Belv Right Floor Primed.jpg)

(56Belv Floor Primed.jpg) (56Belv Floor Primed.jpg)

Attachments

----------------

56Belv Right Floor Primed.jpg (76KB - 226 downloads) 56Belv Right Floor Primed.jpg (76KB - 226 downloads)

56Belv Floor Primed.jpg (97KB - 219 downloads) 56Belv Floor Primed.jpg (97KB - 219 downloads)

|

|

| |

|

Member

Posts: 30

| Just a fantastic job Nathan ! It's much more difficult to do this kind of massive work,and be true to the original profiles and stamped patterns,even though it all will be hidden under rubber mats or carpets..I've done it the same way,and for me,it's gives me greather satisfaction just to know it's done right. Curious to how you made round lowered area where the body mount bolt is ? Took me hours of hammering to make mine,and they didn't come out this nice.. |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Thanks Geir. I asked the guy in Finland who makes the floor braces to press a bunch of body mounts in a panel for me. He put about 8 of them in a single panel and sent them to me with the floor braces that I purchased. Unfortunately, they turned out to be too deep for the '57-'59 floors, but almost perfect for the '55-'56. So I just cut them from the panel and weld them in where needed. It makes it easier than trying to make them myself. Ideally, I would have the roller dies to make my own panels, but my shop is too small for that so I have to make do with what I can.

I obsessed over the small imperfections and went over the floor 3 more times, fixing imperfections that I could see, especially up along the top weld and the innermost line. I got it to a point that I am happy with, other than the lower section that I still have to hammer up from the bottom, so I am going to leave it for now. I have run out of time to work on the left side so I put the seat back in; and I'm going to work on the power disc brake conversion & motor now so that hopefully, I can get it driveable.

(56Belv Right Floor.jpg) (56Belv Right Floor.jpg)

Attachments

----------------

56Belv Right Floor.jpg (74KB - 214 downloads) 56Belv Right Floor.jpg (74KB - 214 downloads)

|

|

| |

|

Member

Posts: 30

| Wow,is there a guy in Finland,here in Scandinavia,that makes parts for old Mopars ? Never heard of him..? I've done with the bodywork on my wagon ( I hope ),but still curious to know who this guy is,and what parts he fabricates..?

Nathan,you can move on to other issues with this car,with the satisfaction of a great job done with these floors,and,I shure will be following the opcoming tasks with brakes and engine..

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Yes, he sells them on ebay under the user name: eriksson1765. He just makes the braces that go under the floor and the floor panel at the seat mount for the '57-'59 cars.

https://www.ebay.com/sch/eriksson1765/m.html

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I dug into the nice paint job on my pedal assembly and welded a brake light switch mount onto it. Would have been much better to have done this before painting, but sometimes I'm not as smart as I would like to be. But it looks decent after repainting. I'm using a Japanese switch because it's all-metal and actually cheaper than the all-plastic GM version.

I also mostly finished the modifications required to the AAJ 12" disc brake conversion to make it work with my Plymouth hubs. There is a quite a bit of fab work required to make it work so it isn't as quick as just assembling a kit. But I like the final results. I used this conversion on my white '56 Fury and the brakes worked really well, to the extent that I was able to test them on it.

(56Belv Brake Light Switch.jpg) (56Belv Brake Light Switch.jpg)

(56Belv 12in Disc Conversion.jpg) (56Belv 12in Disc Conversion.jpg)

Attachments

----------------

56Belv Brake Light Switch.jpg (145KB - 220 downloads) 56Belv Brake Light Switch.jpg (145KB - 220 downloads)

56Belv 12in Disc Conversion.jpg (103KB - 222 downloads) 56Belv 12in Disc Conversion.jpg (103KB - 222 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

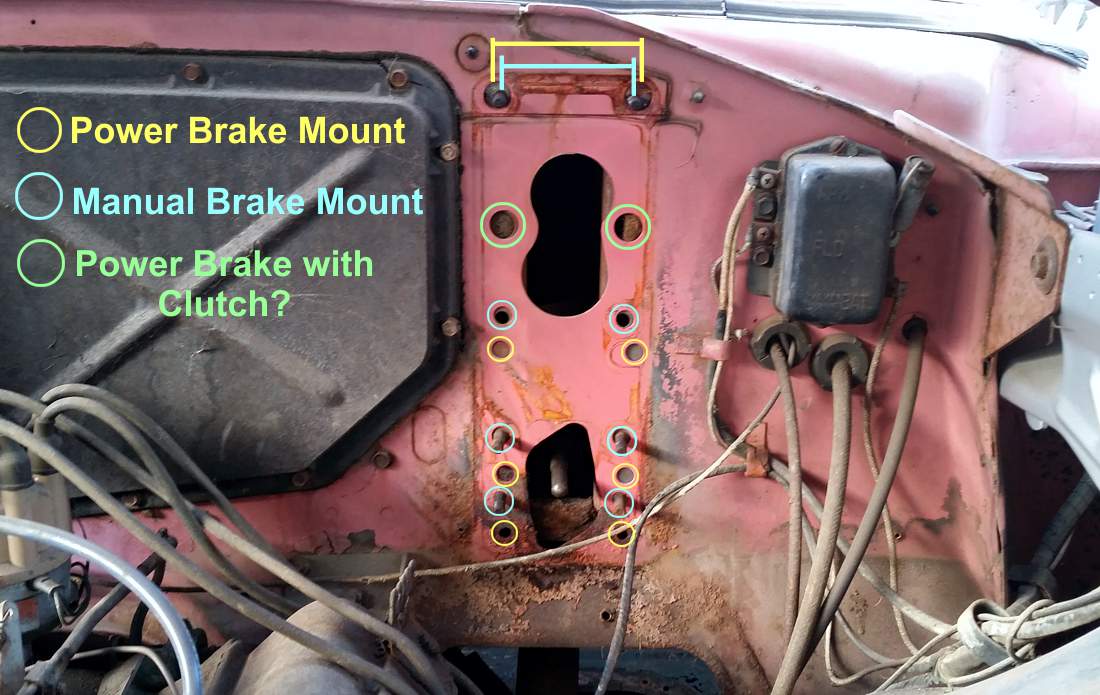

Location: So. Cal | I was a little surprised to find out that the manual pedal assembly mounts completely differently from the power brake pedal assembly. The upper part of the mount isn't even the same width. They've made the holes in the firewall extra large to accommodate the difference in width between them. The master for the power setup also sits much lower than the master for the manual brakes. That accounts for the extra large hole in the firewall down there. I'm not sure what the holes in the middle are for, but I suspect that they are used by the power brake setup for cars with manual transmissions. I guess it's fitting that a Swiss army knife design like this ends up looking like Swiss cheese.

Edited by Powerflite 2021-05-20 11:01 AM

(56Belv Firewall Brake Pedal Mount.jpg) (56Belv Firewall Brake Pedal Mount.jpg)

Attachments

----------------

56Belv Firewall Brake Pedal Mount.jpg (138KB - 206 downloads) 56Belv Firewall Brake Pedal Mount.jpg (138KB - 206 downloads)

|

|

| |

|

Expert

Posts: 1740

Location: Alaska | I believe the reason for the difference in the master mounting between manual and power is for the pedal ratio difference. |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Yeah, that makes sense, but this made me realize that it would make it difficult for me to convert my savoy to power brakes as the lower master would end up colliding with the hemi valve cover.

I installed the power pedal assembly and it fought me the whole way. I didn't realize that the two little brackets that mount to the dash were specific to the car. Every make is different. So I had to transfer my old ones to the new pedal assembly. After I got it all in, the mounting position at the dash was too wide for some reason. It's like the pedal assembly had been widened out. I think I had to straighten it at one point and might have got it a little too straight. So I had to take it back out and smack it with a hammer against my anvil to get it back to the proper width. After taking it back out again to keep from clamping the insulation with it, I managed to get it all together. It fits well now and I didn't have to modify the pushrod so that was nice.

I'm glad that I took the time to make up extra brake lines when I was converting my white Fury to discs, as it made it really easy to install the new lines into this one. I'm waiting for a union for the rear line and I still need to mount the hoses to the frame, so I'll do that tomorrow. I don't have an extra vacuum can for the Plymouth/Dodge, but I am converting a '56 Chrysler can to work on this car. I just need to move & modify one of the legs to make it mount well on the Plymouth. Now would be a good time to convert to power steering as well, since I have the steering column down, but I don't have any of the parts for the pump setup so it'll have to wait for another time.

Edited by Powerflite 2021-05-22 2:35 AM

(56Belv Power Brake Booster.jpg) (56Belv Power Brake Booster.jpg)

Attachments

----------------

56Belv Power Brake Booster.jpg (138KB - 206 downloads) 56Belv Power Brake Booster.jpg (138KB - 206 downloads)

|

|

| |

|

Expert 5K+

Posts: 7403

Location: northern germany | Love this thread. Beautiful car, great work. I will never buy and never ever bought restored cars. This one would be the exception. |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Thanks Sid. I probably won't fully restore this car as it is for my daughter who doesn't care what the engine bay looks like, but I'll clean it up as I go. Eventually, it should look nice as I work on different parts of it.

The vacuum tank had a hard dent in it that I didn't notice before. I was contemplating using a stud welder on it, but I remembered that it sometimes causes a hole that needs to be welded back up, and I didn't want to have to deal with that on this. Then I realized that I could pressurize it and use the pressure to take out the dent as I heat it up. My son is gone for summer job training, so my daughter stepped in to help me instead. She held the pressure while I heated it up. I plugged the other hole with a pipe plug to make it easier. It worked out amazingly well. It's really close to being perfect now and was amazingly easy to do.

Edited by Powerflite 2021-05-22 2:48 PM

(56Belv Vacuum Tank Dent Fix.jpg) (56Belv Vacuum Tank Dent Fix.jpg)

Attachments

----------------

56Belv Vacuum Tank Dent Fix.jpg (166KB - 214 downloads) 56Belv Vacuum Tank Dent Fix.jpg (166KB - 214 downloads)

|

|

| |

|

Elite Veteran

Posts: 655

Location: Finland | That was some smart thinking to fix the dent that way. Not to recommend on fuel tanks though! |

|

| |

|

Member

Posts: 30

| Great work as always Nathan. What M/C are you using,and do you know the bore ? And,hey,it's good to see a youth like your daughter working on old cars ! Gives hope for the future ! |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Yeah Ralf, probably wouldn't be smart on a fuel tank! My daughter enjoys helping her father, but unfortunately her interest in cars goes only as far as driving to where she wants to go. Still, I can't complain because she's awesome. The master is for a '73-up Mopar with 1.032" bore diameter. A very similar master that I used on my white '56 Fury, and it worked out really well.

I have the brake system all tightened up and bled with Dot 4 brake fluid now. The pedal feels firm and tight with no sponginess. But I haven't bled the rear brakes at all. That's an indication that the rear brake hose is likely plugged up. It was the same way on the Fury. I'll just leave it like that for a while until I get it ready to drive. I'm still waiting to receive the 1/2" hose in the mail to hook up the vacuum tank, but the dent is practically non-existent now with zero filler applied. It just required that I slap a small ripple in it down, and sand it out with a layer of primer over it. I'll have to remember that trick for the future.  I didn't bother to take out the small dent at the edge of it. I probably should have, but I didn't mind leaving it there. Next, I'll get some wheels on it that are compatible with the discs, and work on getting it driveable. I didn't bother to take out the small dent at the edge of it. I probably should have, but I didn't mind leaving it there. Next, I'll get some wheels on it that are compatible with the discs, and work on getting it driveable.

(56Belv Vacuum Tank Painted.jpg) (56Belv Vacuum Tank Painted.jpg)

Attachments

----------------

56Belv Vacuum Tank Painted.jpg (122KB - 192 downloads) 56Belv Vacuum Tank Painted.jpg (122KB - 192 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I spent some time to clean up the dash on this car. I didn't think my daughter would appreciate the rusty looking dash, so I decided to clean it up and give it a coat of paint, just to make it look a little better. It's a semi-gloss, but it should flatten out to more of a sheen finish over time. I also pulled the plug for the lighter and added one in there as I am sure my daughter will require one for her phone. I am undecided if I will convert the speaker cover to the later version or not, but in the mean time, this one looks much better after it's cleaned up. I really like the look of the red power brake pedal with the pink dash. Matches quite well  . But I really need to replace that accelerator pedal. It looks pretty bad. . But I really need to replace that accelerator pedal. It looks pretty bad.

Edited by Powerflite 2021-05-29 10:49 AM

(56Belv Dash Cleaned.jpg) (56Belv Dash Cleaned.jpg)

Attachments

----------------

56Belv Dash Cleaned.jpg (115KB - 196 downloads) 56Belv Dash Cleaned.jpg (115KB - 196 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I posted this on facebook and found that my car isn't the only one that was born without a lighter. The lighter seems to have been a separate option on these cars.

(56Plym Lighter_Radio Delete.jpg) (56Plym Lighter_Radio Delete.jpg)

(56Plym Lighter_Radio Delete_Aftermarket Guages2.jpg) (56Plym Lighter_Radio Delete_Aftermarket Guages2.jpg)

Attachments

----------------

56Plym Lighter_Radio Delete.jpg (147KB - 201 downloads) 56Plym Lighter_Radio Delete.jpg (147KB - 201 downloads)

56Plym Lighter_Radio Delete_Aftermarket Guages2.jpg (63KB - 195 downloads) 56Plym Lighter_Radio Delete_Aftermarket Guages2.jpg (63KB - 195 downloads)

|

|

| |

|

Expert 5K+

Posts: 9910

Location: Lower Mainland BC | Powerflite - 2021-05-29 7:44 AM

I posted this on facebook and found that my car isn't the only one that was born without a lighter. The lighter seems to have been a separate option on these cars.

Probably depends on the model. On the Belvederes it was probably standard. For the Savoys and Plazas, it was probably optional.

As an example for 1955 Dodges, the cigarette lighter (Actually "CIGAR LIGHTER") was option No. 443 but it was standard on the Custom Royal and Royals and an extra cost option on the Coronet.

Edited by 56D500boy 2021-05-29 12:23 PM

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | Except that this car is a Belvedere, and it appears to have the lighter deleted from the options. Odd that it would have so many expensive options like the hollywood wheel, dash clock & bumper wings, yet not have a lighter, but that seems to be the case. I had always thought the headliner in this car was a white cloth like my other cars, but it turns out that it was originally a pink color. I pulled these small remnants from behind the dome lights. The rest of it just looks brown.

(56Belv Pink Headliner.jpg) (56Belv Pink Headliner.jpg)

Attachments

----------------

56Belv Pink Headliner.jpg (102KB - 205 downloads) 56Belv Pink Headliner.jpg (102KB - 205 downloads)

|

|

| |

|

Expert

Posts: 1740

Location: Alaska | Could it be that your Belvedere was purposely designed to mimic the Dodge LaFeme but Plymouth didn't have an official name for it? |

|

| |

|

Expert 5K+

Posts: 9910

Location: Lower Mainland BC | 58coupe - 2021-05-30 8:45 AM

Could it be that your Belvedere was purposely designed to mimic the Dodge LaFeme but Plymouth didn't have an official name for it?

Here is another pink and white 56 Belvedere Sport Coupe that was purchased *new* for a daughter:

" For the record, this color is called “Briar Rose”. It reminds me of Dodge’s La Femme models for 1955 and 1956, boy those were sure colorful! The seller says this is a “rust free CA car that was purchased new in the Bay Area.” It was purchased by a father as a graduation present for his daughter when she graduated from Stanford. "

REFERENCE: https://barnfinds.com/pepto-plymouth-1956-plymouth-belvedere/

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I've never thought about a connection between the pink Belvedere and the Le Femme, but could be plausible. Mine is a California car as well, but I wish it were more rust free than it is. But eventually, it will be.

I replaced the fuel pump on the car because the old one was shot. Got it running again out of a gas can, and then for some reason, I couldn't get it to fire anymore. Turns out the connector on my coil got twisted and shorted itself out. I moved it and it fired right up again. So I put the radiator back in and started to fill it with water, only to find it literally pouring out of the bottom of the water pump. That's not going to work. I checked the status of the pump from my rusty fury, and it seems to be good. At least it isn't pouring out when I put water into it. I'll swap that in to see if that fixes the problem, otherwise, I'll have to put a later 318 pump into it because I don't have time to rebuild the original.

I then filled the trans with 5 quarts of oil until it registered full, and drove it back & forth on my driveway. Reverse seems to have good power & torque, but the forward gears are less impressive. Not sure why that is. Another problem is that every time I press on the power brake pedal, the engine struggles to keep running. I suppose that means there is an inner seal that is leaking vacuum? I bench tested it with a vacuum pump before I installed it and didn't notice anything leaking. Also, it seems that the brakes are always on, to some degree, unless I pull up on the pedal. When I pull up, the tang presses on the button on the back of the booster, and it stops boosting. But that tang doesn't seem to be pulled into place by the spring. How is that supposed to work? I don't remember having issues with it on my other cars.

Edited by Powerflite 2021-05-31 1:18 AM

(56Belv Fuel Pump Replaced.jpg) (56Belv Fuel Pump Replaced.jpg)

Attachments

----------------

56Belv Fuel Pump Replaced.jpg (137KB - 206 downloads) 56Belv Fuel Pump Replaced.jpg (137KB - 206 downloads)

|

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I swapped the water pump from the motor in my rusty '56 Fury over to this car and gave it a shot. I made a new gasket before I put it in and it came out OK. After putting it back together, I noticed a small leak in the thermostat neck. So I removed that and welded up two holes in it, and also gave it some material on the inside where it had become thin. I put it back together and so far it seems to be working great. No issues at all, including with the heater core & valve. So the cooling system is good to go now.

I also adjusted the brake push rod to reduce the slack in it, and that seems to have, at least partially, solved the problem with it. I'll look into it more as I start to drive it. I adjusted the timing one more time, and at that point it was ready for a test drive. So I started out and noticed that the brake calipers are hitting the wheel every time I hit the brakes. Doh! The tire people had balanced the wheel using stick-on weights that were deep inside the wheel, and those were hitting it when it extends out. I continued to drive up the street a bit, and turned around when the motor died. It ran out of gasoline, when I still have plenty of gas for it. I don't know what happened if the carb became plugged or if my new pump died for some reason. I gave it a shot of fuel to get it going again, and it wouldn't turn over. The starter solenoid decided to die at that point too.  It figures, just my luck. So I walked back to the house and had my lovely wife push me back home. She really hates doing that, so I'll probably be sleeping in the dog house tonight...except I don't have a dog... It figures, just my luck. So I walked back to the house and had my lovely wife push me back home. She really hates doing that, so I'll probably be sleeping in the dog house tonight...except I don't have a dog... |

|

| |

|

Elite Veteran

Posts: 655

Location: Finland | The first small testdrives tend to be events to remember(forget?). That is typical to have not one issue but two or three at the same time then. Never never go anywhere without

cell phone.. |

|

| |

|

Expert 5K+

Posts: 9679

Location: So. Cal | I'm one of the few people left that doesn't own a cell phone. Occasionally, I've had one through my work, but I just used it as a camera.

I feel really dumb. The starter relay wasn't working so I replaced it with a new one that I had. After I installed it, it still didn't work. So I checked it out and realized I had to put the transmission in neutral first!   When the motor died, I neglected to put the car back into neutral. Not the first time I have made this dumb mistake either. The old relay works perfectly fine! When the motor died, I neglected to put the car back into neutral. Not the first time I have made this dumb mistake either. The old relay works perfectly fine!

The rubbing on the wheel turned out not to be from the wheel weights, but from an extra large blob of weld on the rim that was hitting the caliper. So I cut down the obvious excess blob on the rim and also cut down the clearance chamfer on the calipers where it was hitting (circled in the photo), and now it doesn't rub any more. The fuel pump seems to be working fine, so I'm still not sure what caused it to run out of fuel when it did. I'm going to clean the carburetor inlet with carb cleaner, and clean out the filter as well, and hopefully that will fix it.