That motor looks different now. I went from

flat black to gloss black on the intake and I had the intake bolt covers powder

coated red to match my distributor and my plug wires. I call the engine

the "Black Widow" and the car "The White Coffin".With that 3500 rpm converter,

3.91 gears and a 28 " tire it scoots along pretty well. 4.30 gears and a

28" tire or 4.88's with a 30 inch tire will all lessen its time at the quarter

mile. No, I haven't run it yet but I'm getting really itchy.

My old ugly car. With the good motor.

I'm sure you would enjoy the motor, or one just like it, in your car. Just

buy a bigger cam for more power. Make the compression ratio with a thinner

head gasket. There is enough room in there now for a cam with over .700

lift, but the rocker arms and valve stems can only take a .650 lift cam.

You can get the 700 lift cam but the heads are best at very close to that and

you would have to spend some money to get everything to

clear.

Those freaking old Mopar engines make huge torque

at the bottom with most any cam except the biggest race cams. Don't need a

stroker engine to do it either.

As long as we can show our taillights to the fords

and chevys, we don't have to be beautiful. Just fast.

LOL!

Chick

------- Original Message -----From: Eric SturgisSent: Friday, June 24, 2011 2:28 AMSubject: Re: 440 Change over,, "Advise/Tec help"You know I ment to tell you, that motor would look so good in my car. Such a pretty motor in an ugly car. LOL j/k

On Thu, Jun 23, 2011 at 8:53 AM, Stephen Andrachek <s.andrachek@xxxxxxxxxxx> wrote:

As many times as I proofread my memo, l see errors now. I don't mean you want torque to start coming in at like 5,000 rpm's, but that's the way a sentence in a below paragraph sounded to me. Most every engine on the planet crossed torque (they are exactly the same) at about 5240 rpm. On my engine, at 3000 rpm I'm already pulling 307 ft.lbs. there and it keeps going up to 562.2 torque and 572 hp at I think at 5,900 rpm and at 571 hp at 6200 rpm. But I think you need to build your engine lighter and if you don't beat the crap out of it like I do, you can have a lighter cam and a different rear end for better gas milage. The carb has to be tuned different on the dyno because the carbs and the exhaust are wide open and they can control things from outside the engine room in case something breaks bad or a fire starts. My engine was run at only 140 degrees and on 93 octane gas, both of which costme horsepower. I would have hit just over 600 HP with room to grow with not too much money, far less than building a new engine costs.The engine will richen up when you put mufflers on and even more with the air filteron unless you have a very unrestrected air filter or a cold air intake and a little screen filter (not for the street). You have to rejet every time you change something and carter's (Edlebrock's now) sells the Thunder series carbs (hand choke) or some other series costing more with electric choke. That's the way to go, the electric choke and a jet and metering rod kit from Jeg's or your local guy, if you have one. Running rich after bolting in your engine is expected because the makers of the carb don't want you to blow up your engine by being too len. Better safe than sorry.One 750 should do you well. My engine never hit over 700 and there was 1,500 cfm available. Here is where a good intake is important. Hughes has the dope on that too. Go to their home page and read the technical articles there and you can find what you are looking for and they test a lot of manifolds and three of the best for big blocks turned out to be the old BB two four barrel setup from Edelbrock, the six-pack intake. This is all for small port-heads, not max wedge sized head ports.For max wedge heads the best were the original ones at a very even low 300 cfm intake on each port. Other intakes vary as much as over 60 for all types of intakes and Hughes can make all of them better, some more-so than others. The Indy Big Sucker (very high and has huge ports) is aboutr $640 and flows more air through the port than the port to the engine does. That's the ideal and pick your intake with care AFTER reading some test articles. Check out what magazines like "Mopar Muscle" and "Mopar Action" are building and testing. They are a good source to say what Hughes doesn't and have some good tips themselves and advirtise all things Mopar in one of the Mopar mags and pick up all the info you can by reading, looking and asking questions. I'm no know it all and I'm learning a lot here. Most questions I don't have an answer for so I don't give any advice. Then I learn by reading the other comments. I like the idea too of having the answers sent to everyone and the private emails are great too, but I's always curious as to how things turn out and it seems like everyone is doing that anyway and I like it that way.If you call for parts and Hughes asks you why you want that kind of part with the other parts you are buying? It won't work good with those parts. This other part will give you more HP for maybe less cost, same cost or a litttle more cost.I dealt with Hughes and I highly recommend them. They are all Mopar all the time and very nice and helpful and they will have most of what you need. You can get most anything for a RB (what Hughes calls a BB) so don't get confused. The site looks a little intimidating at first but isn't hard to use at all. Look at the tech articles. Look at the HP and Torque. Click on those charts to make them bigger. Check out what works with what. Hint, the wilder the cam, the better the heads, intake, etc. are what makes all engines go and makes them suitable for the street, street/strip or all out racing.Chick (more below, belive it or not)----- Original Message -----From: Stephen AndrachekTo: Gary PavlovichSent: Thursday, June 23, 2011 4:24 AMSubject: Re: 440 Change over,, "Advise/Tec help"Gary,Good flowing heads, a cam of about 220 to 230 degrees duration , a 108 centerline and about .530 lift with a good 4 barrel intake and a 750 Edelbrock or a 750 or 780 Holley-type carb should get you to where you want to be or even a little better or a lttle closer. I like the Edelbrock carbs which were formerly Carter carbs. They are easy to tune and usually too rich out of the box and really too rich if you are using two of them, no matter what kind of intake you are using. You have to use a high volume fuel pump they sell with no more than 7 lbs pressure and it can move a lot of gas per hour. Something suitable for a Holly or Holly type cars, like the pressure from the fuel pump or the fuel injection can run up to over 45 lbs. So all components must be matched to each other to make them work well together.Hughes Engines can fix up your heads and port them a little. Leave the stock pistons in if you aren't pulling the pistons out. If your are, you can attend to any other necessary matters. If not, you can either buy cores from Hughes and buy the heads from them and have them ported or not. Or you can send in your own heads and have at least a stage I pocket port job put on them. This and the cam are going to give you your power. The compression ratio works like this. A higher compression ratio forces you to use higher octaine fuel but you don't get much HP back as you go up the compression ladder, you have to use two to five highter octane gase to get, at most, 5% more power. So keep the motor no higher that 9.25 to 1. My motor is about 8 to 1 and makes all kinds of horsepower. I left room to grow by simply changing cams and intakes and carbs. It would make more than 100 more HP but would cost another $3,000 or more to get that hundred. The stock 8 3/4" rears on stock MOPAR with heavy duty universal joints for the driveshaft and the rear and front of the shaft, all of that and the trans is good for 600 HP at the flywheel engines.This is a pretty simple way to build a pretty good cruising engine. Mine cost of lot of money but if you read the Dyno Runs on Hughs you will learn a lot about what works a lot better than I can. But most of their engines are all out of max HP. However, some of the engines work for cars right up your alley. Heavier, torque you want to come in low, hard and fast. 5500 to 6000 rpm is probably fine enough for you. A high torque low end cam with the right grind can do both. Of course, the hotter the cam the higher up the rpm range you want to run the engine, the more cam people want. I'm only using the third-hottest solid lifter Hughes cam and its perfect for my car, makes mucho low torque, mucho HP to 7000 rpm and I don't have power brakes and power steering so vacuum pressure doesn't bother me.A hydralic cam might be better for you. Don't go too conservative with an RV cam. Don't go overboard either. You should find the right cam about the second hottest hydralic (not RV) cam to the fifth hottest hydralic cam.Of course if you change one thing, like I changed the heads, you might (or most probably will) have to change other things too. causing more problems. Sometimes it is just better to use all you can of what you have and only change the most critical parts if the engind is in good shape otherwise. Modify what you have to to make it last and be right and still keep to your budget, if you have one, might be expected to go down the drain real quick.Do get rid of the stock MOPAR rocker arms. They only have a true 1.37 or near the true lift ratio. Plus both the rocker arms are steel and so are the shafts. That is just asking for trouble. You don't put steel bearings on a steel crank because it will scratch it all up and the motor will seize. Hughes adjustable rockers are available for $450 a set and are highly recommended. They come with shims and you should get their special tool and a dial indicatior to make the right size pushrods with.I just so happen to have a Hughs brand-new set of rocker arms and shafts. No needle bearings to break, a true 1.5 ratio (PUSHRODS FOR AN HYDRAULIC CAM ALREADY MADE AND BRAND NEW TOO), spacers, special lube, the whole 9 yards. I'll sell it at a good price but I can't give it away. I wouldn't work with my original Max heads because the part that holds down the rocker arm shafts are one-piece and if you manage to thread one through and then tighten them down, if everything isn't lined up perfectly, when you tighten the bolts you crack the shaft. You have to have the split hold-downs in your heads that are in two pieces and one is cast into the head, the other comes off with the bolt holding it on and then you take the old out and put the new in. If you want to get a cam from Hughes and the other stuff from me (and you won't have to pay a big deposit on their pushrod sizer and mine was fairly warm and should work with whatever you buy with no problems) and want your pushrods perfect to .001 inches, you can go through the extra effort with new ones from Hughes or buy mine. They are so good they rarely need adjusted, evey by guys who have race cars with this type of rocker arm and they only adjust their valves one a season and that is mostly just to be sure. They really hold their adjustment.Trans-go makes three different types of trans kits for older mopars than my 62. They are all for firm shifts. The first is an RV type kit. The second is a street/strip type kit with more line pressure and still you can user "Drive" and it will shift so good you don't even know its there or hold it forever in first or second with the buttons or whatever you have. Maybe you want a floorshift. Another $300 for the best. If your trans cables are shot try to get some used ones on the cheap. New ones are almost impossible to find unless you want to pay $300 or $400 per cable. One thing with the trans'go. I go no. 2. When the guys rebuilt, and they do old racing MOPAR 727's all the time, there is a piece in the directions that say to take the lip off one side of the piece and put it back in the trans. This doesn't work. Leave the lip on or you will have to take the trans out, find a factory one and put it in. The third one is full-race with a reverse pattern and you have to shift all the time. What's the use of having an auto unless you are only racinging it?If you want any more advice, read the stuff on Hughes Engines and it will be a big help. They will also answer questions for you happily. So will I;can use a Dvorak one way screen for a windage tray and supposedly pick up 10 or 12 extra HP. The best part is that if you blow the crank, the one was screen keeps the cranshaft and piston rods from going through the oil pad during a race at the track or any other place. Something might get through the block, but the oil pan, unbroken, will still hold most of the oild. It comes with a crank scraper that has to be hand fitted to your engine and has .010 clearance. I use a Milodon 7 qu. pan but I can only use the little fiter cause the big oil filter is a bitch to get in or out.Here's a few pics of the Dvorak stuff when I was building my engine. I've got lots mor stuff to say about the subject of what to put in a 440 engine to get the best of of it (but not too cheaply and I think you can get the job done with the same amount of HP and torque and still be running 87 octane gas and you willl have enought tourque to get a big car moving very quickly and keep on going quicker all the time until you take your foot off the gas. You car will be low compression, have a cam that idles faily smothly without giving away how hot the engine actually is and still have big HP and torgue from way down low (2000 rpm) to way up high (7,000). I don't know how the vacuum on the cam is because my car has no power brakes and no power steering so it doesn't matter to me.I have many pictures and tips you can use or not, I'll send you what I have little. I think you already heard this but I'll tell you again. Don't get in too big a hurry but don't neglect the project by getting tired of it. Sometime family or financial matters keep people from reaching their goals. I know you are pretty determined to get it done right or you wouldn't have bothered to do it in the first place. I already did it to an engine that would work great in your car, providing that you have enough vacuum to work your power stuff. If it doesn't, you can go to the next lower cam and still have a hight HP and torque engine that might be even better for your car. Hughes Engines has exactly what you need. They are on the web. So is Hughes Engineering. Easy to confuse them. The Engines sells all MOPAR engine parts and complete dyno'd engines and Engineering sells all makes of trans and torque convertors for most makes, including MOPARS but the MOPAR trans either is disapper or going way up in price and getting harder to find all the time. Trans-go makes a 1, 2, or 3 kit. No. 1 kit is an RV kit with altered shift points and full auto but you can still control the trans with the buttons if want to like going down a very steep hill and putting the trans in 2nd gear to help slow it down and save the brakes. You are lucky you did'nt have to buy a trans. Then new cables are getting so hard to get, if you can even get them, some places want over 200 dollars each for a speedomoter cable, a shif cable and a park cable. I could have paid 1/3 or less of the price 4 years ago but I waited and got one of the last of each. $529 for three cables that used to be about $150 for all of them. And not teeth in the speedomoter cable. You have to take the teeth out of your old cable and put it in your new cable yourself. If you changed the rear gear ratio it is hard to find a right ratio gear because no one has them anymore. If you live near a guy who has a MOPAR race shop and he carries parts (or not even) he may be able to help you out with some hard to find pieces for your engine and trans. Your car probably not, but he will probably know who does.Anyway, I have a lot more to say later but now I'm going to attach some pictuof my engine and some of what was done to it. You probably will want some more answere after you get into it deeper. Don't be in a hurry, you can get your block hot tanked and sonic tested locally probably and you will need to to check for bore shift and don't make the overbore any higher than you have to. .020 used to be very expensive but doens't cost any more than any other size of overbore now. .030 is more or less standard, .040 lets you get in one more size if it passer the core-shift test, .060 and only some 44o block, never mind the year, can take that much without cracking a cylinder.A cam also depends on what kink of rear end ratio you are running, the diameter of the rear tires, the weight of the vehicle and the intended use. Going as hot as you can while still having great low end torque with the read you are running will give you plenty of power. Just make sure you have enough clearance in your piston to valve clearance and make sure you use the recommend valve springs, retainers, keepers and get your vavle seats machined for new ones if you can afford it on the exhaust side so it will run without wrecking your engine and make sure all the valve stems are the same height. You might have to have some of the valves more sunk into the head to make everything even, Then true up the head with a .oo5 cut and you have to have your intake cut a few thousands too to make it all like up.You can match the heads and the intake to the intake gaskets. A lot of people thing this isn't worth the trouble and the dyno doesn't show much gain for this operation alone. Or with other work done to the engine either. Unless it was off bad I wouldn't bother with it.I used expensive Victor alimunim heads and steel heads that have the right work done on them can make as much HP as my engine, around 600 or maybe 50 less for you if you want a lighter hydraulic cam. Your engine will still go like hell and your power steering and power brakes should work better than with a cam like mine. You don't need a stroker, my engine make great toruqe but the strokers beat it at top end and only get about 100 more torque than me on all-out stroker race engines and I have nowhere to go but up if I want more hp or torque but enough is enough. How much you pay will be more the longer you wait and the more expensive parts you use. So if you only have a 5 qt. pay you might want a bigger one. You may need an alimunim raditor with an electronic fan along with either a deltutching MOPAR factory cam, a flex cam and a shrould, (You are going to need the should need the shrould anyway.) More HP is more heat and you don't want to overheat all the time. You want a reliable car you and drive from coast to coast.

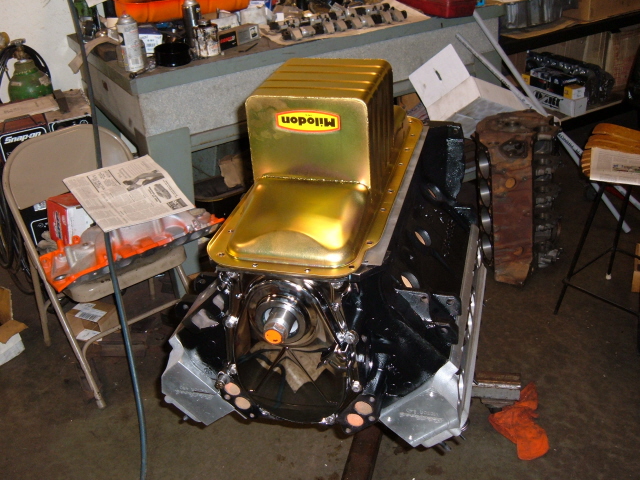

Here's some pics for you. Don't hesitate to ask me any questions. I'll try to get back to you withing a few day, at least. Let me know what you want, what suggestions you got from anyone on this board you would like to incorporate into your engine, etc. Some guys might have better tips than me on how to really do it on the cheap, but it takes being in the right place at the right time, or knowing someone, or looking for a very long time to get all the parts together if you want to do things on the cheap. Even if you buy the best of anything there can still be all kinds of delays. The motor man can take years more to build your motor than he told you he would take. Parts that are supposed to fit don't and have to be modified. Whatever can go wrong sometimes does.Coated bearing are also a good idea. They call it CT-coating but it is reallly Molylibdemum oxide (looks like powered graphite in powdered form). This stuff can prevent a bearing from going out if the engine somehow doesn't get enough oil to your engine. The problem is that MOPARS ard $90 to get your main bearings CT-coated and that doesn't include the cost of the bearings. For a chevy they sell coated bearings complete for $90. Mopars ain't chead to buy, work on or stuff like that but they can be built up to be as fast as any other brand, at least. All of their cars shared mostly the same engines according to the size of the cars and are more valuable than most other brands when done due to scarcity and who wants what? A daily cruiser with a decent motor, a part time cruiser with a street/strip engive, a "hot rod", a custom, a racer, etc., Mopar is always my favorites.Stephen "Chick" AndrachekThe front of my engine when it was going together. Block is black to be different.No wanter pump on yet, I used an alimunim one to hold doen weight.The Dvorak crank scraper being fitted and the Milodon oil pickup sticking out.The Dvorak one way screen/windage tray. It has to be fitted too. More money and youcan get away with a used windage tray to save money if you want.Small view of the bottom with no crank scraper or screen.Engine almost ready to get fired up the first time to seat the gastkets. Hot block with no water in it.Top of block with the best Keith Black Pistons in it.That's it for this time. I've got a lot more pics, a lot more ideas and feel free to ask whatever you want. My way might not be the best way but it won't be far offand it will run good if the parts work together well. That's at least 90 percent of it on any engine.Keep me posted as to how it is going.Chicka warning to the guys with dial-ups. These are full sized pictures and will clog up your machine so, when you get this far, just don't wait for my pictures until I start doing what people keep telling me what to do and how to do it and its a much easier way and more beneficial and what eveyone is telling me how to make life easier and quicker and I just revert to my old ways because I'm a hardhead, I guess. I'm stuck in my old ways and sometimes maybe put too much info in one email.(Now I've got "bullets now by mistake----- Original Message ----- bullet paragrapy markers and ran out of room to put memo in. I done the best I could to put out some good info and I'm not sending any quick-From: "killerjay rodskie" <krodskie@xxxxxxxxx>Sent: Tuesday, June 21, 2011 8:52 PMSubject: Re: 440 Change over,, "Advise/Tec help"Gary, i have a 64 B body 413 ci. factory oil pan and a Mancini Racing Windage tray # P4120998.The Windage tray seems to fit tight in the pan, but Mancini's tec support claims, that is the way it works. i hope it will be OK.

--- On Tue, 6/21/11, 62to65mopar@xxxxxxxxxxx <62to65mopar@xxxxxxxxxxx> wrote:

> From: 62to65mopar@xxxxxxxxxxx <62to65mopar@xxxxxxxxxxx>

> Subject: Re: 440 Change over,, "Advise/Tec help"

> To: 1962to1965mopars@xxxxxxxxxxxxxxxx

> Date: Tuesday, June 21, 2011, 11:42 AM

> Cool!

>

> What oil pan are you using?

>

> Couple pictures here:

>

> http://1962to1965mopar.ornocar.org/ml-boger65.html

>

> http://www.1962to1965mopar.ornocar.com/kailholz651.html

>

> Thanks,

> Gary H.

>

> > > Gentlemen, In the next week or so, we will

> "finally" be

> > > putting together a rebuilt TNT 440 Engine

> that I pulled out

> > > of a 1970 premium model Imperial. The 440

> is going in my 65

> > > Coronet,,which now has a factory 318 Poly

> with power

> > > steering and power brakes.

> > >

> > >

> > >

> > > My fellow Mopar brothers Please!,,Giving it

> some though!,,

> > > is there anything I should be aware of or I

> should consider

> > > doing in order to make the change over go

> smoother and/or

> > > avoid any unneeded stress.

> > >

> > >

> > > Oh!, can someone email me a good clear

> photo of a 65/B Body

> > > Engine compartment with a 440 in it, just

> so that my help

> > > can see what we are somewhat going to end

> up with.

> > >

> > >

> > > PS: Please if possible email me off list.

> > >

> > > Thank you All,

> > > Respectfully,

> > > Jay Rod.

> > > 1965 Dodge Coronet 500.

>

> --

> You received this message because you are subscribed to the

> Google Groups "The 1962 to 1965 Mopar Mail List Clubhouse"

> group.

> To post to this group, send email to 1962to1965mopars@xxxxxxxxxxxxxxxx.

> To unsubscribe from this group, send email to

> 1962to1965mopars+unsubscribe@xxxxxxxxxxxxxxxx.

> For more options, visit this group at http://groups.google.com/group/1962to1965mopars?hl=en.

>

>

--

You received this message because you are subscribed to the Google Groups "The 1962 to 1965 Mopar Mail List Clubhouse" group.

To post to this group, send email to 1962to1965mopars@xxxxxxxxxxxxxxxx.

To unsubscribe from this group, send email to 1962to1965mopars+unsubscribe@xxxxxxxxxxxxxxxx.

For more options, visit this group at http://groups.google.com/group/1962to1965mopars?hl=en.

--

You received this message because you are subscribed to the Google Groups "The 1962 to 1965 Mopar Mail List Clubhouse" group.

To post to this group, send email to 1962to1965mopars@xxxxxxxxxxxxxxxx.

To unsubscribe from this group, send email to 1962to1965mopars+unsubscribe@xxxxxxxxxxxxxxxx.

For more options, visit this group at http://groups.google.com/group/1962to1965mopars?hl=en.--

You received this message because you are subscribed to the Google Groups "The 1962 to 1965 Mopar Mail List Clubhouse" group.

To post to this group, send email to 1962to1965mopars@xxxxxxxxxxxxxxxx.

To unsubscribe from this group, send email to 1962to1965mopars+unsubscribe@xxxxxxxxxxxxxxxx.

For more options, visit this group at http://groups.google.com/group/1962to1965mopars?hl=en.

--

You received this message because you are subscribed to the Google Groups "The 1962 to 1965 Mopar Mail List Clubhouse" group.

To post to this group, send email to 1962to1965mopars@xxxxxxxxxxxxxxxxx

To unsubscribe from this group, send email to 1962to1965mopars+unsubscribe@xxxxxxxxxxxxxxxxx

For more options, visit this group at http://groups.google.com/group/1962to1965mopars?hl=en.

You received this message because you are subscribed to the Google Groups "The 1962 to 1965 Mopar Mail List Clubhouse" group.

To post to this group, send email to 1962to1965mopars@xxxxxxxxxxxxxxxxx

To unsubscribe from this group, send email to 1962to1965mopars+unsubscribe@xxxxxxxxxxxxxxxxx

For more options, visit this group at http://groups.google.com/group/1962to1965mopars?hl=en.